How To Use A Ceramic Knife Sharpener

How to Acuminate a Knife

Updated: Nov. 28, 2017

This elementary, sure technique for how to sharpen a knife requires only two inexpensive tools

Sharpen knives quickly and go on them that way with 2 simple, cheap tools, several easy-to-acquire techniques and a footling practice. It'll make kitchen nutrient grooming much quicker and easier too.

You might as well similar: TBD

How to Sharpen a Knife Must-accept tool #1: A sharpener

Joe Gamache, our adept cutler, says there are hundreds of devices, techniques and theories about how to sharpen a knife. Some sharpening methods are arcane; some ridiculously complicated. However others are only for those obsessed with incredibly sharp edges and crave investing a boatload of coin in gadgets.

Simply Joe has a quick, drib-dead simple approach that he's been teaching to amateurs to learn how to sharpen a knife. You'll only need a couple of inexpensive sharpening tools and a chip of practice. Master information technology and you lot'll exist amazed at how well your knives perform and how much more fun nutrient prep, carving, slicing and peeling can exist. Or at least how much less painful. Read on to learn how to acuminate a pocketknife.

Sharpener choices

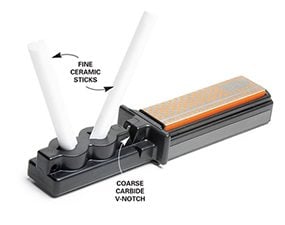

Joe suggests either of two choices for a sharpener: a V-sharpener or, if you're a more serious cutler, a stick sharpener. Each has two sharpening surfaces, ane for roughing out an edge and the other for the final edge. Both styles are piece of cake to use for those learning how to acuminate a knife. But the stick sharpener will probably last your unabridged life. And with that style you lot'll look pretty impressive when your guests watch you sharpen your pocketknife before carving upward the roast.

Meet the Pro! Joe Gamache

Joe has sharpened well over 1 million knives in the past twenty years. And believe it or not, he's only needed 16 stitches. That's less than a sew a year! He'll testify you how to safely achieve sharp edges without any trips to the ER.

Joe says, "To get and go along your knives sharp and truthful, you'll absolutely need ii tools: a sharpener and a steel."

Must-have tool #two: A steel

A steel is the shorthand term for a steel rod used to straighten knife edges. Any decent knife set includes one, simply few people know exactly what it does, much less how to properly use it. If you lot don't have a steel, go purchase ane for nigh $20. Joe volition show you how to utilize it to maintain a sharp edge. Don't waste your money getting a diamond-coated surface. You don't demand it to know how to sharpen a pocketknife.

All the sharpening tools you lot'll demand are available anywhere knives are sold. Get online and search for specific products or generic tool names. Or just visit Joe's store at eversharpknives.com.

How to Use a Pocketknife Sharpener: iii Steps to sharp

Go for proficient enough— not perfection!

Super-abrupt edges are slap-up—at get-go. Then the razor edge speedily dulls. That's considering an border that sharp is necessarily very sparse, and it bends and dulls easily because there's not enough metal to support it. A knife that'll hands piece through food is abrupt plenty. The lycopersicon esculentum test (beneath) will tell y'all when a knife is ready for food prep.

Follow Photos 1 – 3 for the three-stride sharpening process. After sharpening and before any food prep, wipe off the blade with a cloth to remove any metal filings.

Joe says, "Don't strive for razor-abrupt edges—'abrupt-enough' edges stay sharp longer."

When to take your knives to a pro

If yous follow Joe's instructions and still can't go a good edge, chances are your knives take been driveling to the indicate that they demand a pro'south touch to restore the edge. You can practise it yourself, but it takes expensive electrical tools or a lot of tricky manual grinding on a stone. But for well under $10 per knife, a sharpening store tin can bring your edges to better-than-new condition. So you'll be able to keep them that way using Joe's techniques. Search online for "knife sharpening" followed past your city and y'all'll surely discover a local sharpener. And don't give up on high-quality knives that have a chip or notch in the blade. A pro can grind out any imperfections and reshape the edge. Yes, you'll take a slightly narrower blade, merely you won't fifty-fifty notice.

Joe says, "If you melt 5 meals a week, take your knives to a pro for a tune-up once or twice a year."

Use a steel—oftentimes!

Steeling restores the edge

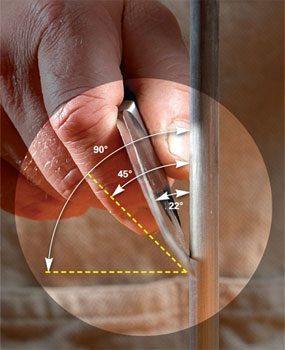

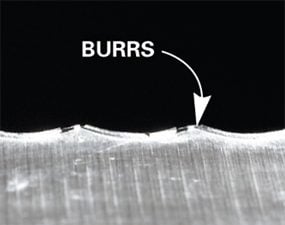

Chefs and meat cutters frequently pause and "steel" their cutting edges. Steeling doesn't sharpen an border; it straightens it. That's necessary because the thin edge actually bends or warps while you're cutting. If you could see the border under a microscope, information technology would look wavy, and it would feel wearisome while cutting. Steeling the knife straightens out all those waves to restore a straight, fifty-fifty cutting edge. Then when your pocketknife begins to seem dull, don't sharpen it—steel it offset. Every fourth dimension yous take hold of a pocketknife for the first time to begin cutting, steel it earlier you even go started. But information technology'south of import to do it right or y'all'll merely make the edge worse. And don't act similar 1 of the Iron Chefs on Television set and do it all up in the air—you'll eventually wind up in the ER. Balance the terminate of the steel on a cutting board and exercise your steeling the safer and more authentic way. It'due south very important that y'all steel at an angle between 20 and thirty degrees. Photo ane shows you how to figure that out.

If your pocketknife isn't restored by steeling, yous may need to hit the fine ceramic stone a few times. Yous should rarely need the coarse notch after your knife is properly sharpened. That is, unless you've wrecked the border by cutting on a too-difficult surface or trying to grunter your way through a bone. If that's the case, you lot'll take to hitting the coarse and and so the fine.

Joe says, "The steel keeps a pocketknife precipitous."

The Purpose of Steeling

Photo A shows what your pocketknife edge looks like after a dinner's worth of cutting—all aptitude and wavy." Photograph B shows what your knife border looks like later steeling. The edge is directly and set up for cutting again."

Video: Paw Tool Hacks and Modifications for Woodworking

The tomato test for sharpness

Joe says, "Lycopersicon esculentum skins are the perfect way to examination for sharpness."

If yous tin can piece through a tomato plant skin without having to saw your fashion through or poke a starter hole with the knife tip, you have a sharp edge that'due south ready for food prep.

Cutting-Edge Tips From Joe

Cut boards:

Drag the tip of your pocketknife across your cutting board. If the surface doesn't scratch, it'due south too hard and it'll dull your knife in no fourth dimension. Some plastics and certainly glass and laminate surfaces won't pass the exam, even if they're called "cut boards" on the label.

Acidic foods:

Rinse knives after cut acidic foods like citrus fruits or pickled goods. Acid promotes corrosion right at the cutting border, even with stainless steel. Dry them right afterward.

Cleaning:

Don't ever throw knives in a dishwasher. Wooden handles will become ruined, and even stainless steel blades volition corrode and get dull. Instead, wash your knives by manus and dry them off right away.

Protect the edges:

Don't just toss unprotected knives into a drawer. Either employ a knife block or stow them abroad with blade protectors. Simple paper-thin sheaths held together with duct tape volition do the job.

Avert bones:

They'll dull fifty-fifty a high-quality knife. Electric sharpeners: Don't e'er use a cheap electrical knife sharpener, especially the ones found on electric can openers. They'll do more harm than good. If you love gadgets, spend at to the lowest degree $125 for a decent electric sharpener. (You'll still take to steel your knives, by the fashion.)

Other knives:

"I acuminate all knives the same fashion—hunting knives, fillet knives, what ever. Keep a mini sharpener in your tackle box and use the aforementioned techniques."

Sharpening serrated knives

Serrated knives can be sharpened, simply unlike ordinary knives, they need a diamond-coated steel that's properly sized to match the knife.

If you desire to master the technique, accept your serrated knives to a knife or cookware store and ask to have your knife matched to the right diameter diamond-coated steel. Its diameter has to match the scallop profiles. If yous take more one serrated knife, choose a tapered steel that'll work for different scallop sizes.

If you examine the blade, you'll see that 1 side is tapered and the other is flat (this is called a chiseled edge). The tapered side is the merely one that gets sharpened. When you're through sharpening, elevate the knife through a bit of corrugated paper-thin to knock off any leftover filings.

Originally Published: September 19, 2017

How To Use A Ceramic Knife Sharpener,

Source: https://www.familyhandyman.com/project/how-to-sharpen-knives/

Posted by: shellenbargerjuplage.blogspot.com

0 Response to "How To Use A Ceramic Knife Sharpener"

Post a Comment